Ultra Thick Safety & Security Window Films

Ultra thick safety and security window films

Klingshield started installing thick safety window films in the 70’s. However, the application of these films has always been difficult. The problem is, the thicker the film, the more difficult the application. Most manufacturers of thick safety film seem to have the same problem - a very slow drying out period due to the thickness, as well as “orange peel” appearing in some instances.

Another problem associated with thick films is that contamination or dust from the edges of the frame is highlighted. Applying thick films to a flat piece of glass without a frame around it is successful. However, once the glass is surrounded by a frame, this makes the installation more difficult.

Each installation needs to be looked at on its merits and a sample should always be applied to the consumer’s window to ensure that they are satisfied with the final finish. In some cases, a double application of a thinner film might be the answer, as the finish is always better than the single ply thick films.

Ultra thick safety films offer excellent smash and grab and burglar resistance and in some cases when the consumer can accept the retro fit finish it is an ideal product for these situations. All Klingshield’s safety and security films are made in the USA and have exceptional optical clarities and advanced adhesive performance that give our safety films the edge over other brands.

Klingshield safety film offers protection from a variety of natural and manmade dangers, assuring our customers safety and complete peace of mind.

Ultra thick safety films come in 170 micron, 200 micron and 300 micron thick. The 200 micron safety film laminated to a tinted film is utilised in the protection of car windows for serious “safety conscious” consumers. All Klingshield’s film comply with AS/NZS2208 Human Impact Standards.

Ultra thick safety films are up to six times thicker than normal films and can be applied to clear float glass, laminated glass, tinted glass, toughened glass or wired glass. If applied to wired glass it must go on the smooth side of the glass.

Natural disasters, tropical storms, tornados, hurricanes and earthquakes all turn ordinary glass into lethal dangerous glass and often come without warning. Consumers should not be unprepared and should have safety film installed on all glass areas to prevent injuries from flying glass. Terrorism and violence is a thing of our modern society. Here at the dawn of this new century the world finds itself challenged by terrorism which intends to create destruction of life and damage to property. Industrial accidents happen all the time due to human error at work sites. Klingshield’s safety film reinforces the glass and holds it in place to prevent glass fragments flying at high speed, injuring personnel and damaging property.

Theft and break-ins are on the increase as the world economy deteriorates and more and more people are desperate. The ultra thick safety films offer virtually impenetrable entry for would-be burglars or smash and grab attackers. Safety film holds glass together and helps isolate fires preventing them from spreading into other areas. Ultra thick safety films also come with solar performances. Sputter coated 100 micron and 200 micron safety film offer a dual reflectivity, elegant appearance, while reducing the eye strain and glare that comes in from natural windows.

Sputter coated safety films block 70% of the suns energy, keeping one cool even on the hottest day.

Further, interior furnishings are shielded from the deteriorating effects of fading that often comes from direct sunlight.

Physical properties of 200 micron Safety Film

- Tensile Strength (PSI-ASTM D882) 29,505

- Break Strength (lb/inch – ASTM D882) 375

- Elongation at Break (1% - ASTM D882) 140

- Peel Strength (g/inch – ASTM D3330) >2850

- Puncture Strength (lb/force – STMS D4830) 146

Benefits

- For use where security is the main issue.

- Manufactured to comply with AS/NZS 2208 Human Impact Standard when applied to 3mm glass and thicker.

- Popular for glass strengthening with a visibly undetectable clear appearance.

- Over 5 times as thick as normal film, increasing the strength and security of glass.

- Holds shattered glass together reducing risk of injury.

- Scratch resistant coating.

- Maintains duty of care.

- Physical properties of 300 micron Safety Film

- Tensile Strength (PSI – ASTM D882) 27,318

- Break Strength (lb/inch - ASTM D882) 301

- Elongation at Break (1% - ASTM D882) 159

- Peel Strength (g/inch – ASTM D3330) >1550

- Puncture Strength (lb/force – STMS D4830) 184

Benefits

- For use where security is the main issue.

- Manufactured to comply with AS/NZS 2208 Human Impact Standard when applied to 3mm glass and thicker.

- Popular for glass strengthening with a visibly undetectable clear appearance.

- Over 7 times as thick as normal film, increasing the strength and security of glass.

- Holds shattered glass together reducing risk of injury.

- Scratch resistant coating.

- Maintains duty of care.

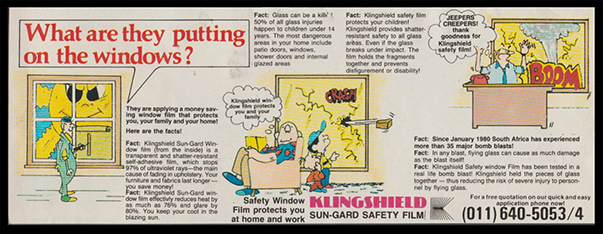

Safety window film ads for newspaper advertising

Watch the video below