Window Film Specifications | Klingshield

Klingshield Film Specifications

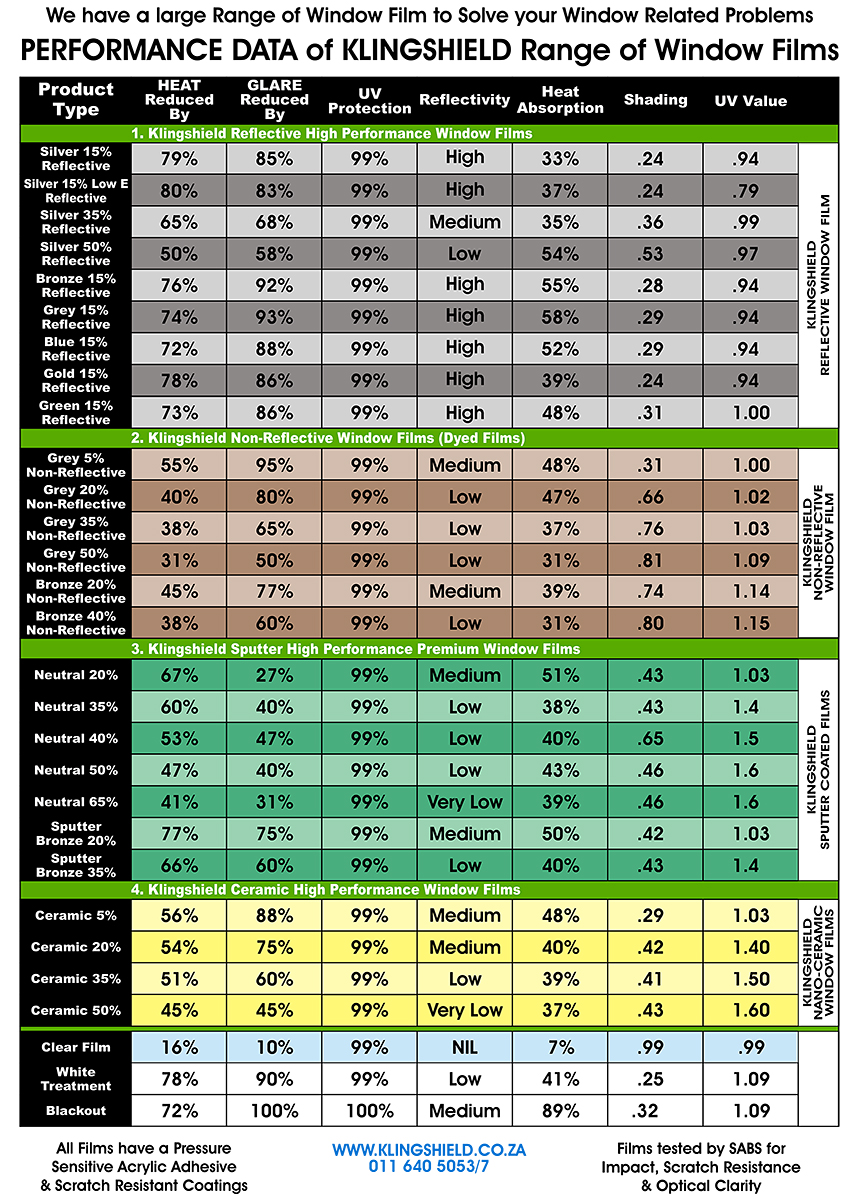

PERFORMANCE INTRODUCTION

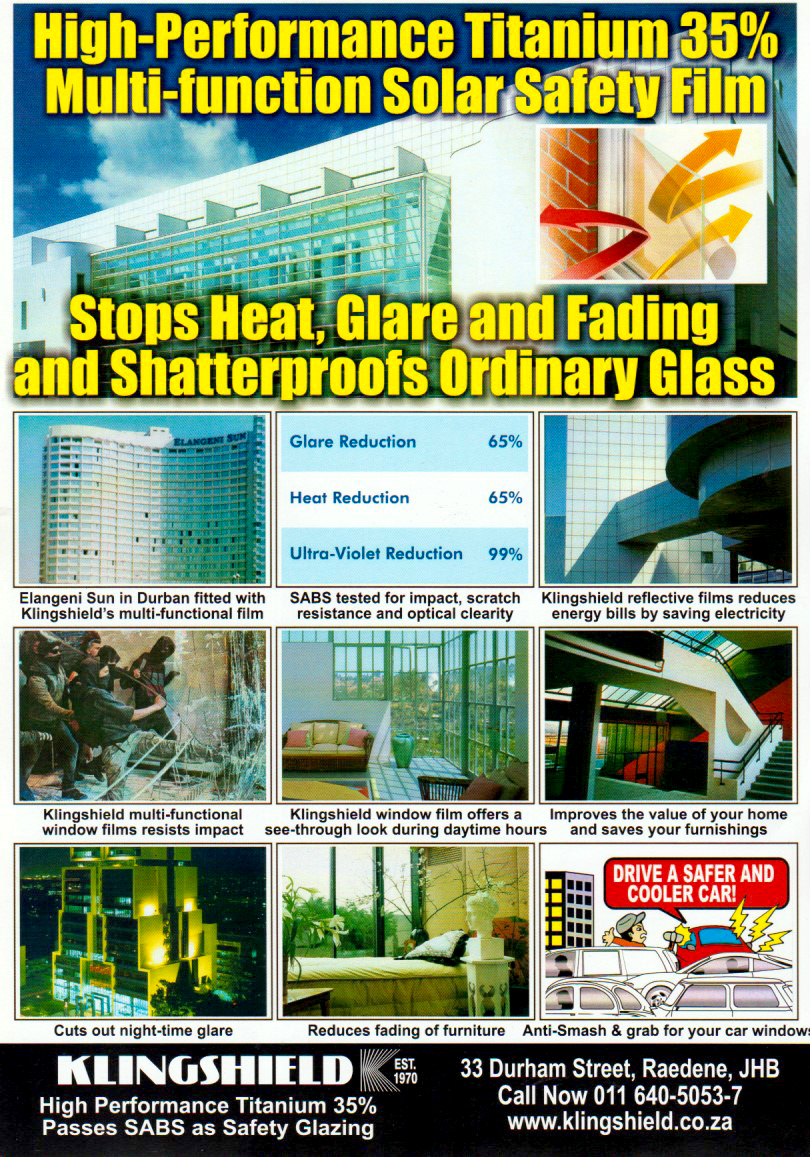

In the summertime radiated solar heat and glare can make your life uncomfortable at the office, home or shop floor.

As the temperature rises your work efficiency falls. Often hot temperatures bring out hot tempers.

Even window blinds cant keep you cool they just keep out the light. Klingshield’s performance film range of technically advanced solar insulating film works all year round to even out temperature highs and lows. In summer the film reflects back the worst of the sun’s heat and reduces glare, while still allowing the light through.

In winter certain films reflect escaped heat back into the building. Many buildings fitted with Klingshield’s solar films have benefitted from dramatic savings in airconditioning and heating bills.

PRODUCT TESTING – SAFETY FILM

Klingshield safety films conform to and have been tested to the following international standards:

-

ANSI Z97.1.1984 (1./4” Tempered Glass)

-

ANHSI Z97.1.1994 (1/4” Annealed Glass)

-

ANSI Z97.1.1984 (1`/8” Annealed Glass)

-

British Standard BS 6206:19812 – Category C & B

-

Structural Performance ASTM E-330

-

Impact Test Aftger Aging-ANSIZ97.1-1984

-

ASTM E84 – 0Aa-Fire-Propagation Test

-

British Fire Propagation Test – BS476 Part 6

-

ANSI Z97.1 Adhesion/Tensile Strength

-

ASTMD3330 Peel Strength

It has been endorsed by the US Department of State and Army Corp. of Engineers and is in use by the governments and embassies worldwide.

Our films have also been subjected to stringent tests under simulated conditions conforming to international and CSIR and SABS requirements.

- Tested for distortion

- Resistance to abrasion (scratch resistant tests)

- Resistance to impact

- Resistance to weathering

- CSIR bomb blast tests – 6mm glass with applied plastic sheeting

- Post Office Telecommunications impact tests

- All these tests are available should you require full test reports.

Product development is an ongoing process in almost every industry, with the window film industry being no exception.

Continual refinement and improvement have resulted in our “new generation” window films for treatment of window glass for homes, offices, factories and motor vehicles.

Optical clarity so precise, almost unbelievable with light absorption qualities to reject the harshest glare, as well as 99% protection from the harmful effects of the ultra violet light radiation, are all provided by our range of window products.

Our new high tech window films are fashionable, good looking and stylish, with tremendous emphasis being placed on performance from lighter density films with protection from the sun and heat. An increased product life expectancy and improved adhesion, together with the now-benefits of protection from stone throwers, smash and grab attacks, petrol bombs and explosions.

Converting ordinary glass into solar glass and achieve cost effective and meaningful reductions in heat and glare whilst easing airconditioning plant loads with the application of Klingshield’s Window Films.

While all Klingshield window films are available for internal application, certain films are suitable for exterior applications only.

Once the film is applied, it is not easy to detect it as film. Rather the film lends its appearance to the glass.

The specifier may select from films which are clear, tinted, reflective, semi-reflective or ceramic. Various colours and tints are available – see above.

WHERE TO USE KLINGSHIELD FILM

All clear glass - single thickness – float glass

All Klingshield films are recommended for application to this glazing system.

Clear shatterproof laminated glass or solar shield glass

Only silver reflective films are recommended to this glazing type. This type of glass builds up heat between two panes. Coloured films absorb more heat than the silver reflective films. The combination of coloured films and shatterproof or solar shield glass can produce more heat build up than the glass can tolerate.

Heat absorbing shadow light

All Klingshield’s silver reflective films in 20%, 35%, and 50% densities are recommended. Tinted glass functions by absorbing the heat and holding it in the glass. Coloured film (reflective and non-reflective) also absorb heat. This combination can produce more heat build up than the glass can tolerate.

Dark tinted heat absorbing glass

All Klingshield silver films are recommended. Please note the darker the window is tinted, the lighter the silver film is recommended.

Reflective glass

All films are recommended, preferably silver. Caution – please determine whether the glass has a history of breakage and if so, silver is a must.

Frosted, textured or wired glass

Because the glass has been edged, carved or contains wire, it has already been weakened. Not recommended for film application unless owner accepts risks. No guarantees offered.

Acrylic or Perspex

Some Perspex or acrylic have had film applied successfully. However, each product has different expansion and contraction and once film has been applied, the film can cause ridges to form on large sheets. No guarantees offered.

Polycarbonate or Lexan

All Klingshield films are recommended for this application. A pressure sensitive film must be used. Dry adhesive films will not bond properly to polycarbonate.

Armourplate or tempered glass

All Klingshield safety films can be applied to armourplate or tempered glass.

THE ABOVE INFORMATION IS PURELY OUR RECOMMENDATION

Klingshield assumes no risk or liability for glass breakage whatsoever!

N.B. Insert independent testing for Sun Control Municipality. Available from Klingshield

Fill out my online form.